Welcome

Meet Custom

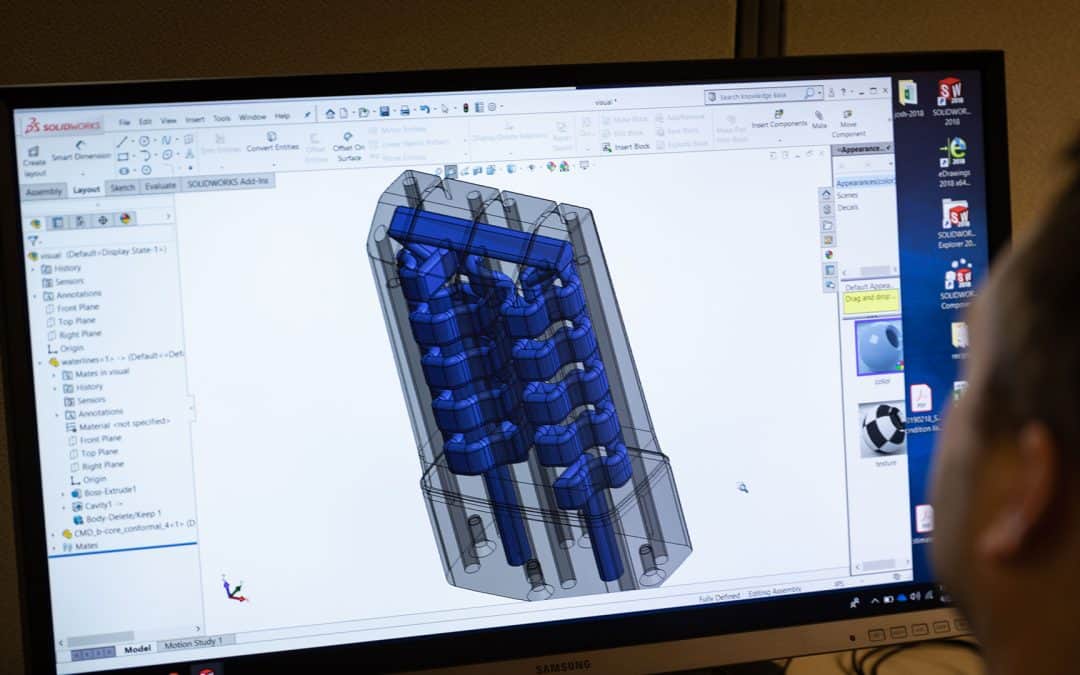

Mold & Design

Rooted in excellence since 1965, Custom Mold & Design is the industry leader for designing and building high-precision, fast cycling molds, machined components and fixtures. Custom Mold & Design offers an extensive array of mold types, catering to a diverse range of industries. We have expertise in various advanced mold technologies including multi-cavity, multi-shot, metal injection, silicone and micro molding. Custom Mold & Design stands out for our ability to create molds that meeting the exacting demands of our clients.

SOLUTIONS

We Bring Your Big Ideas to Life

Custom Mold & Design has the expertise and capabilities to take your next project from concept to completion.

Explore our comprehensive tooling design & manufacturing services for medical, aerospace and defense, industrial, communications, and consumer applications.

Design Support & Engineering

Tool Design & Fabrication

Precision Machining

Mold Maintenance & Repair

Tool Sampling

Quality Assurance

MARKETS

Specializing in Highly

Regulated Markets

Custom Mold & Design has the knowledge, certifications, and cutting edge equipment to make complex, highly-specialized molds & tooling for high-compliance industries. From collaboration in the pre-design phase all the way through product delivery our dedicated team of engineers, technicians, and solution architects is ready to take on your most challenging projects.

RESOURCES

Meet Your Innovation Partner

Find more information about us in our Case Studies, White Papers, and Brochures, or stay up-to-date by following our News & Events section.

Media Kit

PDFs

Videos

Velosity Earns Prestigious Minnesota Safety Council Governor’s Workplace Safety Award

April 16, 2024 | Dedication Secures Gold Standard Recognition FOREST LAKE, MN. (April 16, 2024) - Velosity, a leading contract manufacturing organization for medical devices, will be honored for its outstanding commitment to workplace safety and health during the 2024...

Company Overview Brochure

Welcome to Custom Mold & Design When you need the highest quality, performance and design, turn to the industry leader for designing and building high-precision, fast-cycling molds, precision machined components and fixtures. Custom Mold & Design (CMD) offers...

Conformal Cooling: A Practical Application

Introduction Conformal cooling is not a new technology, in fact, many articles have been written about this topic over the years primarily as a means to reduce cost and improve quality in injection molded parts. There are countless examples of parts that were...