SOLUTIONS

At the Forefront

of Innovation

Custom Mold & Design stands at the forefront of innovation, specializing in the conception and fabrication of precision-engineered injection molds. Our expansive repertoire encompasses an array of mold types, including high-precision injection molds, multi-cavity molds, two-shot molds, metal injection molds, silicone molds, micro molds and ceramic molds.

We proudly hold certifications in ISO 9001 and AS9100, underscoring our commitment to stringent quality management. Custom Mold & Design holds the distinction of being ToolingDocs certified mold maintenance provider, a testament to our proficiency in upholding mold longevity and performance. In addition, our ITAR registration highlights our alignment with international regulations, reinforcing our capability in managing defense-related products and services.

SOLUTIONS

We Bring Your Big Ideas to Life

Custom Mold & Design has the expertise and capabilities to take your next project from concept to completion. Learn more about our services for medical, aerospace and defense, industrial, communications and consumer applications.

Design Support & Engineering

Tool Design & Fabrication

Precision Machining

Mold Maintenance & Repair

Tool Sampling

Quality Assurance

OUR PROCESS

Proven Performance

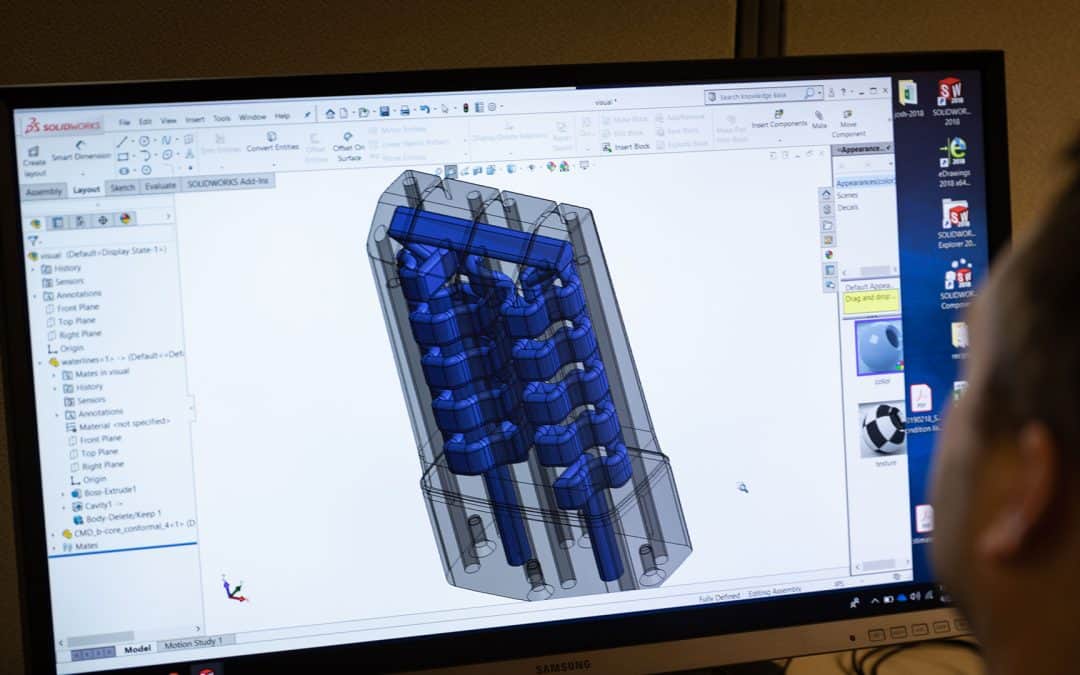

At Custom Mold & Design, our team of talented engineers and mold makers utilize cutting-edge CAD/CAM systems to cater to the dynamic demands of our valued customers. Leveraging the proficiency of our skilled engineers and mold makers, we provide the essential creative input needed to make optional decisions for superior outcomes. Our customers trust us to deliver top-notch solutions tailored to their mold making requirements.

RESOURCES

Meet Your Innovation Partner

Find more information about Custom Mold & Design in our Case Studies, White Papers, and Brochures, or stay up-to-date by following our News & Events section.

Media Kit

PDFs

Videos

Velosity Earns Prestigious Minnesota Safety Council Governor’s Workplace Safety Award

April 16, 2024 | Dedication Secures Gold Standard Recognition FOREST LAKE, MN. (April 16, 2024) - Velosity, a leading contract manufacturing organization for medical devices, will be honored for its outstanding commitment to workplace safety and health during the 2024...

Company Overview Brochure

Welcome to Custom Mold & Design When you need the highest quality, performance and design, turn to the industry leader for designing and building high-precision, fast-cycling molds, precision machined components and fixtures. Custom Mold & Design (CMD) offers...

Conformal Cooling: A Practical Application

Introduction Conformal cooling is not a new technology, in fact, many articles have been written about this topic over the years primarily as a means to reduce cost and improve quality in injection molded parts. There are countless examples of parts that were...

Best in Class Comprehensive Solutions

Check Out Our

Parent Company Velosity

Velosity, the new parent company name for Teamvantage, MMD Medical, CMD Custom Mold & Design, CMD Precision Manufacturing Group, and Paradigme Engineering, is an industry leader in fully integrated custom contract manufacturing, solving medical device original equipment manufacturer (OEM) customers’ toughest challenges by providing strong problem-solving capabilities to help customers achieve repeatable solutions with a long-standing track record of success.

Velosity’s comprehensive suite of end-to-end solutions, including:

- Injection molding

- Contract manufacturing

- Precision machining including dry Swiss machining

- Finishing and assembly

- Packaging